Bolted Joint Stiffness

a Short explainer on what is Bolted Joint stiffness and how can it be calculated

Bolted joint stiffness refers to the resistance of a bolted connection to deformation when external loads are applied.

Bolt joint stiffness is critically important in mechanical design because it directly affects the load distribution, joint integrity, and reliability of bolted connections.

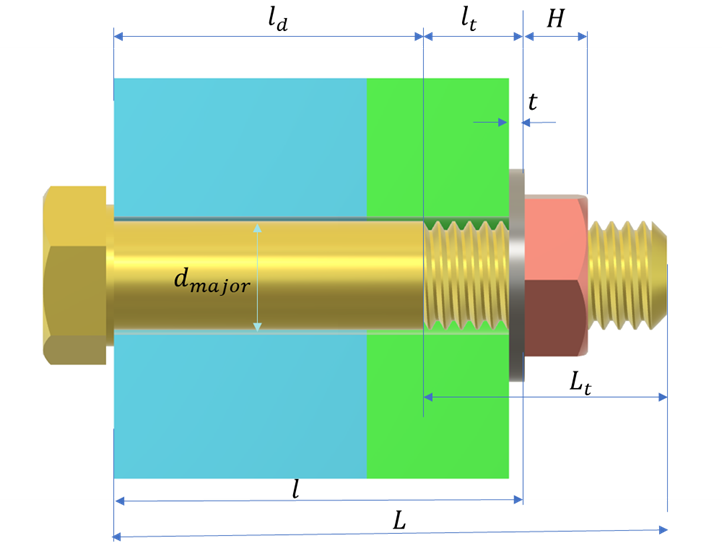

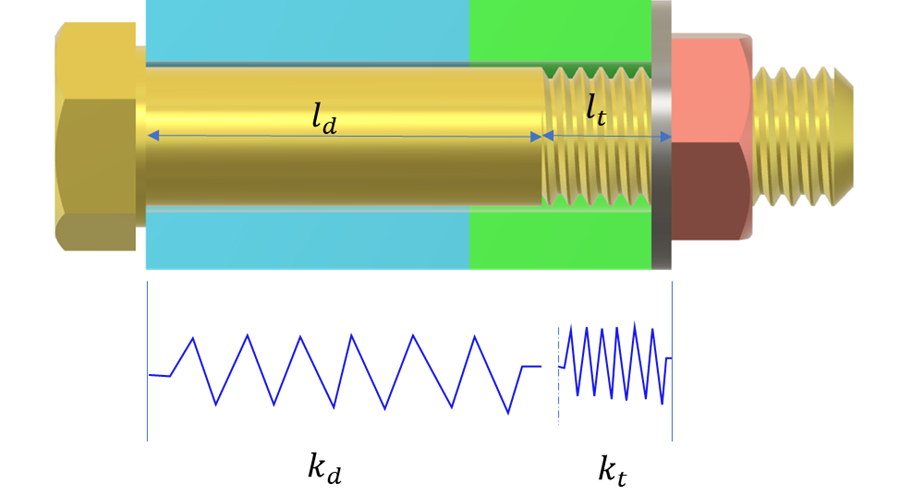

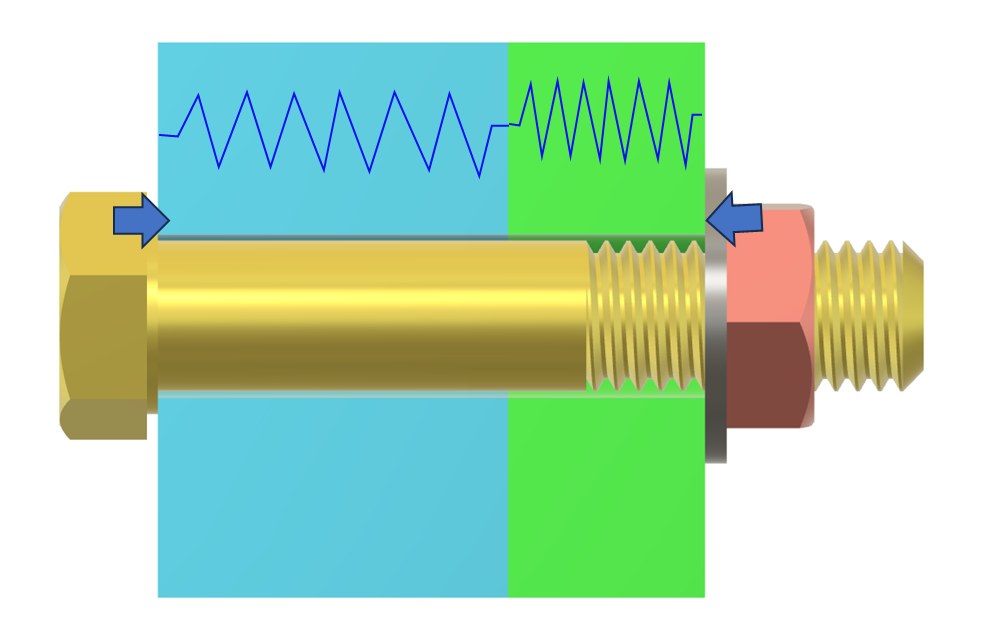

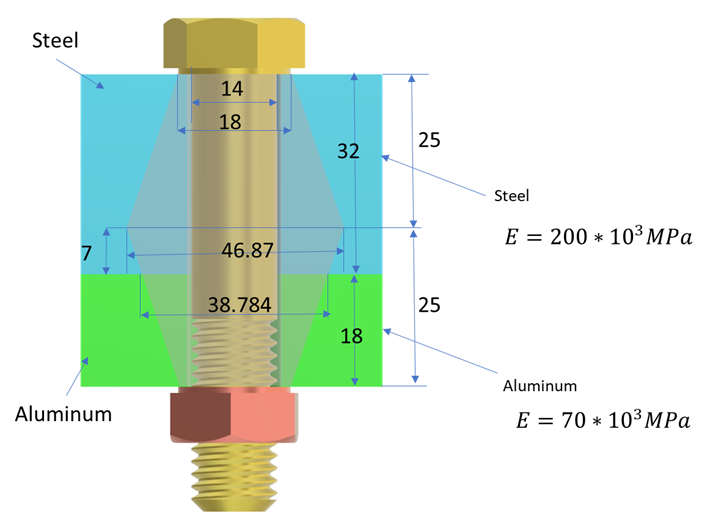

Cross sectional view of a bolted joint:

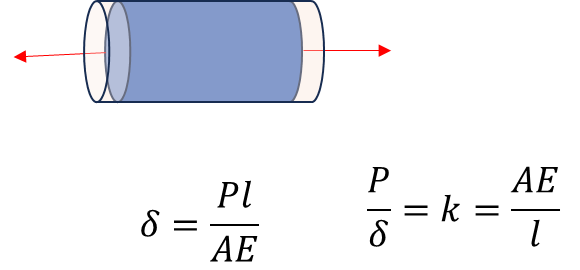

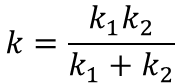

Consider a rod being pulled apart (tension)

Its deflection and stiffness is given by :

P is the force, l is length of rod, A is cross sectional area and E is young's modulus

Using this we can find the stiffness of the bolt as it behaves like a rod in tension .

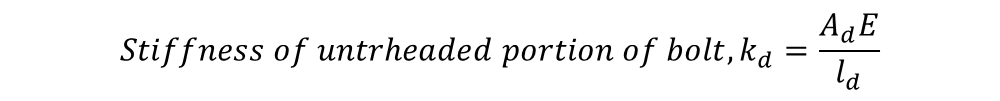

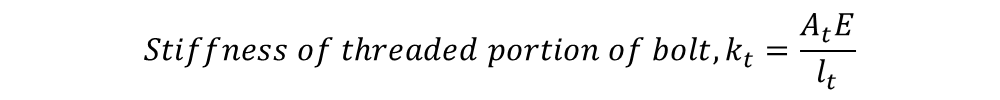

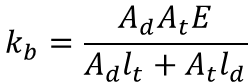

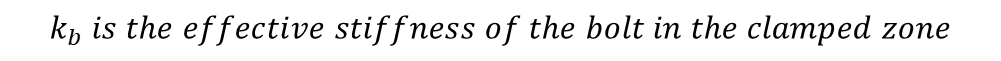

The bolt axial stiffness is due to two portions – unthreaded and threaded. They both act like springs in series.

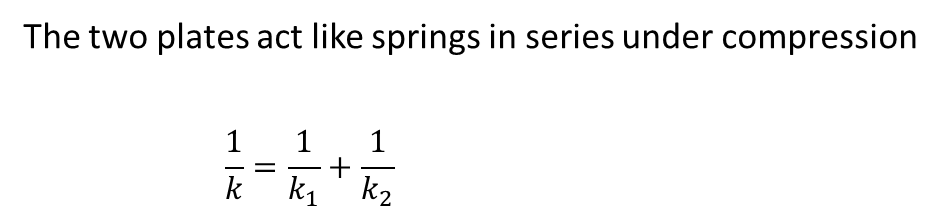

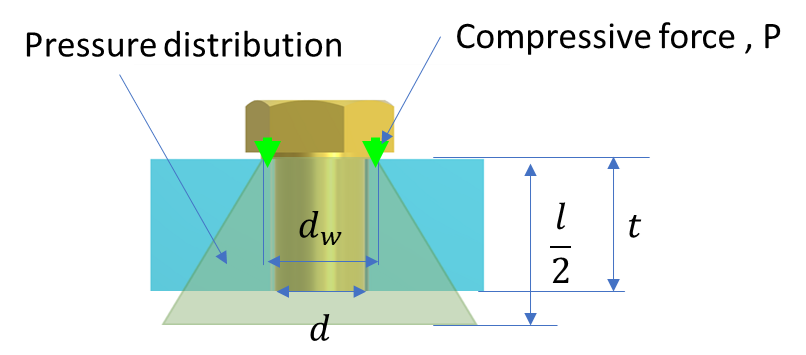

Member stiffness :

Calculating the stiffness of the member or plate which is being fastened is equally critical in the loading direction .

Through analysis and experiments it was found that The compression is not uniform

It spreads out in the form of a frustum of a cone as shown

This is called the Rotchers Pressure cone

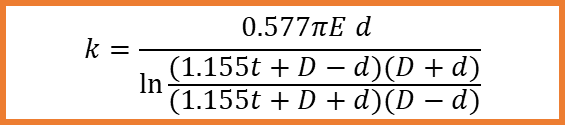

The Member stiffness using Rotchers Pressure cone is given by

d is the clearance hole diameter

D is the diameter of washer or resting face of bolt

t is the thickness of member

Example Problem :

Find the member stiffness equations for the setup .

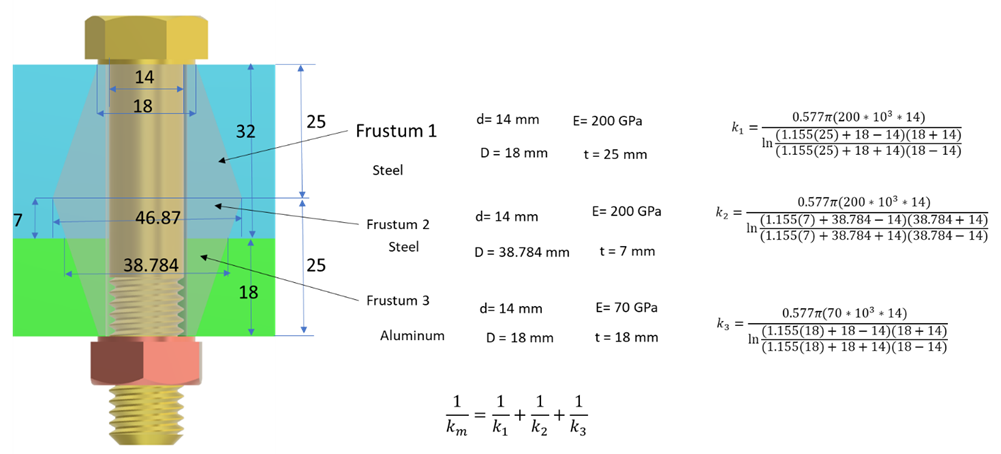

There are three sections

Fructum 1, Fructum 2 and Frustum 3

Frustum 1 and Frustum 2 are in steel while Frustum 3 is in Aluminum member

The stiffness for each frustum can be calculated using the formula shown above with parameters as shown in the middle.

Effective stiffness can be calculated with the formula for members in series.

Categories: : Mechanism and Machine design

Mufaddal Rasheed

Mufaddal Rasheed