Torsion Spring Design

A short article on key parameters for torsion spring design

Torsion springs are essential mechanical components used to store and release rotational energy, making them crucial in applications ranging from garage doors to automotive systems. Designed to work by resisting twisting forces.

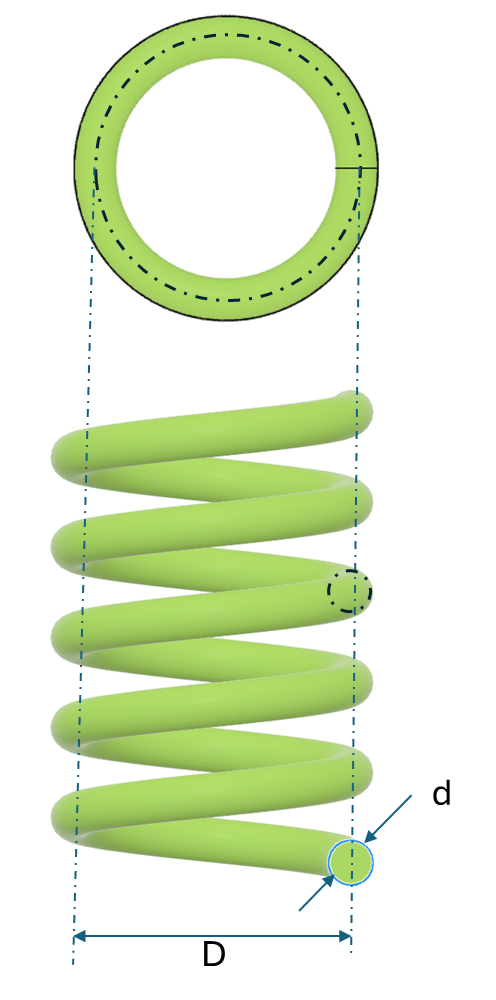

Torsion Springs are Helical coil springs subjected to end torsion like a shaft .

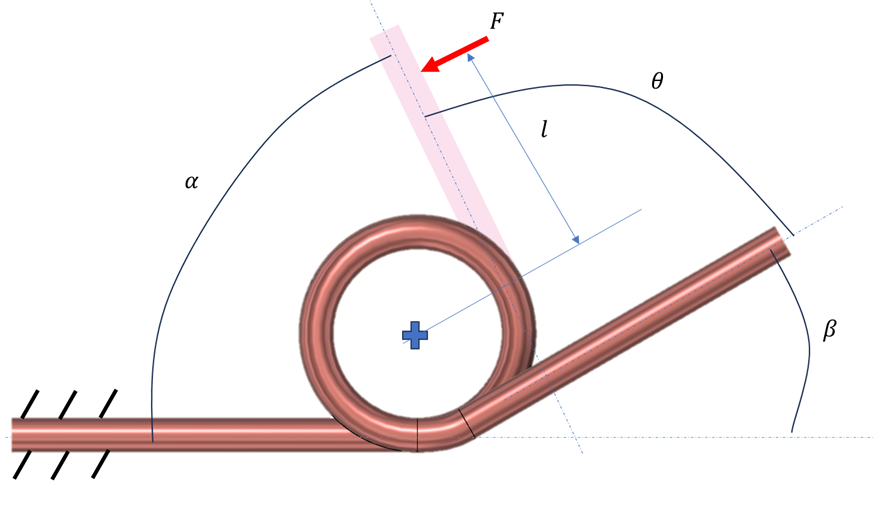

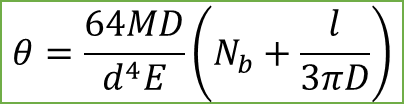

The key design parameter for torsion spring is the End Deflection and Bending stress developed on the inside of the coil .

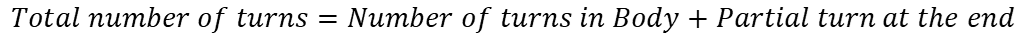

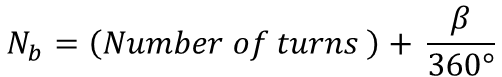

Total number of turns in the coil is given by

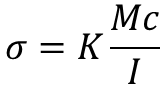

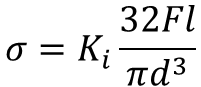

Bending Stress in the wire is key limitation for design .

d is the wire diameter in mm

F is the Force applied in N at a distance ‘l’ from the center of coil in mm

Ki is the Wahls factor

E is the Youngs modulus in N/mm^2

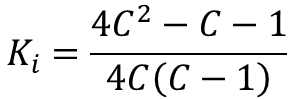

Wahls Factor :

Wahl's factor is a correction factor used in spring design to account for the additional stress caused by curvature in helical springs, particularly in compression and torsion springs

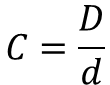

Where C is

D - Coil diameter

d - Wire diameter

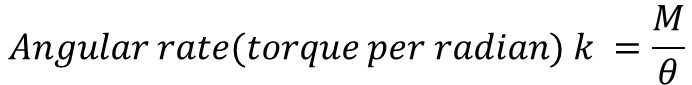

Spring rate of a Torsion spring is measured by its angular rate

How much Torque or Force is required to rotate the end of torsion spring for unit angle

Otherwise called torsional stiffness

The Angle of deflection for a given force can be calculated using the formula.

Categories: : Mechanism and Machine design

Mufaddal Rasheed

Mufaddal Rasheed