Von Mises Stress

What is Von Mises Stress and what is the theory behind it? A short article on distortion energy theory in theories of failure in mechanical design

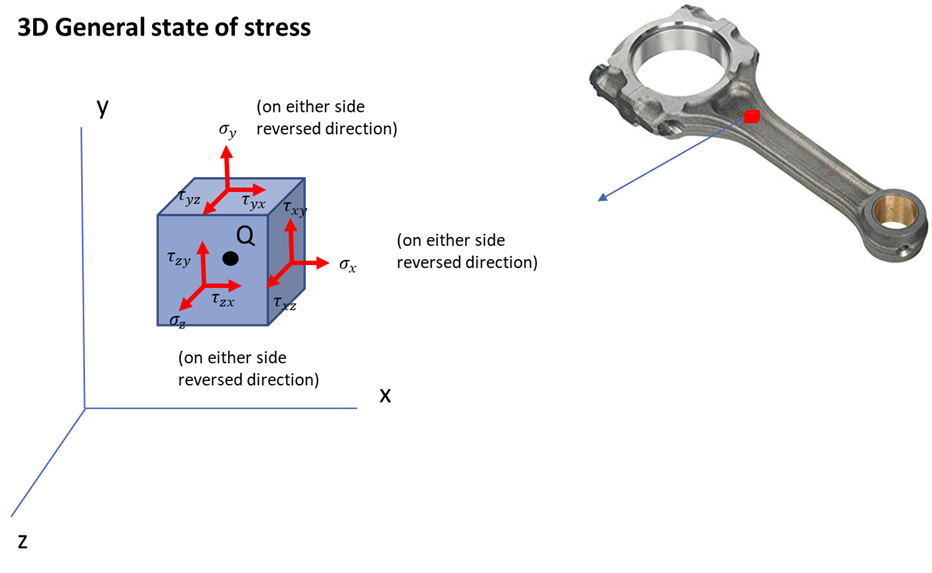

Any infinitesimal 3d element (a cube) on a component (which is undergoing loading) will experience normal and shear stresses.

This state of stress is called 3D general state of stress

Here is an example of a very small 3d element cube in a connecting rod.

On each Face of the cube the state of stress will be as shown :

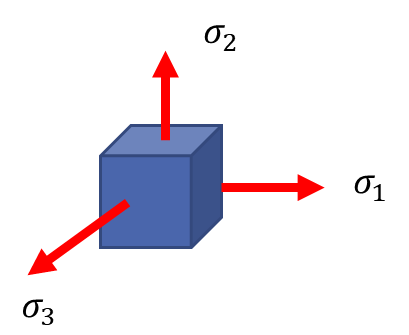

If the Element is rotated with respect to a co rodinate axis , it is found that one specific 3D orientation all shear stresses will be zero.

At that orientation , the normal stresses in x , y z directions are called principal stresses

To understand the concept of distortion energy we need to first understand what is strain energy

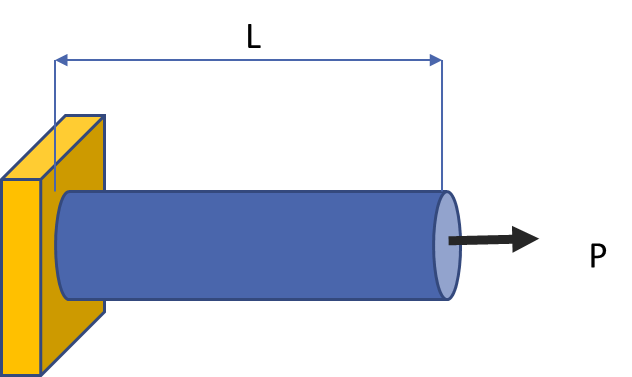

Now consider a rod with a force P and a length L being pulled .

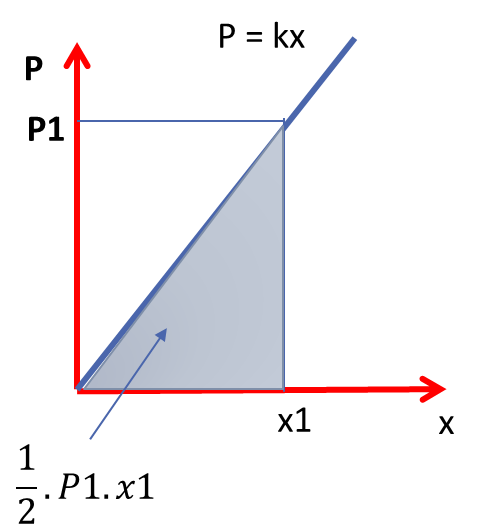

Load – Deflection curve :

Another important term is strain energy density . Strain energy Density is strain energy per unit volume.

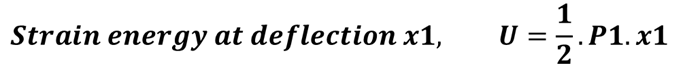

Stress strain curve for the same uniaxial loaded rod.

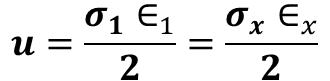

Strain energy density for an axially loaded rod

Strain energy density for shear :

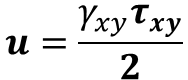

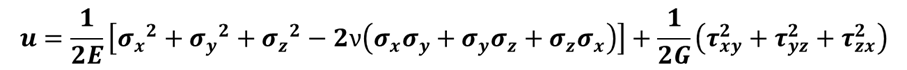

For 3D general state of stress:

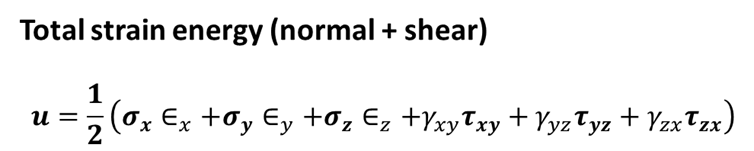

Normal and Shear Strain is a function of :

where v is Poissons Ratio.

After substituting ,

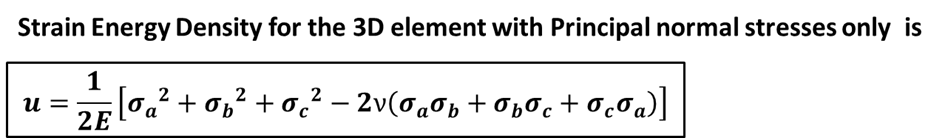

If we consider Principal Normal stresses, then shear stresses are zero .

Only the first term of addition remains with principal normal stresses.

A number of tests were carried out by scientists to ascertain the mechanism of failure of ductile materials .

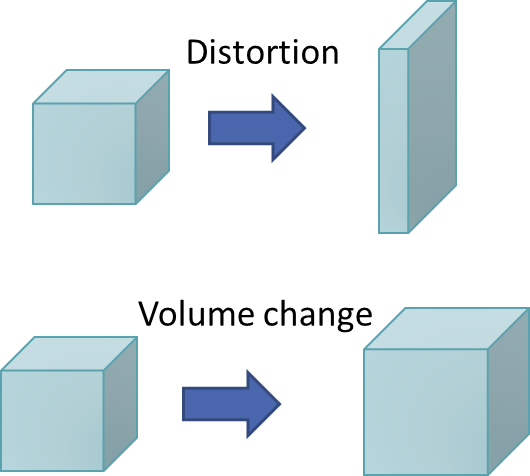

The inference from these tests was that the yielding was not only a simple tensile or compressive phenomenon rather it was related to the distortion of the elements. Distortion is change in shape

The energy associated to the change in shape of the material is the culprit in causing failure compared to the energy required to change the volume of the material.

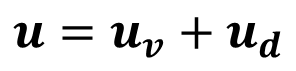

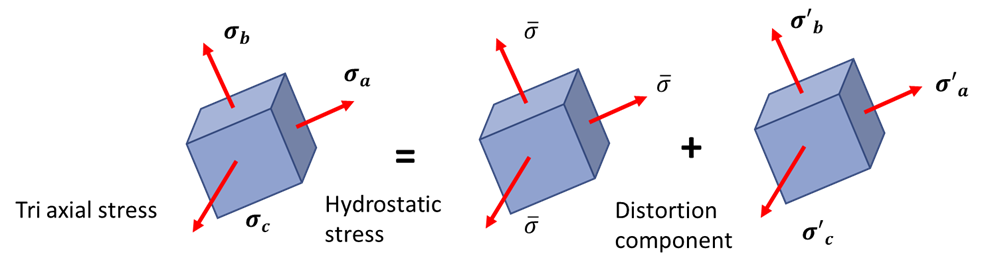

strain-energy density u at a

given point or element is divided into two parts, a part associated with a change in

volume of the material at that point, and a part associated with

a distortion, or change in shape, of the material at the same element

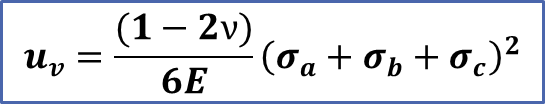

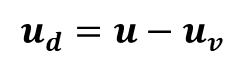

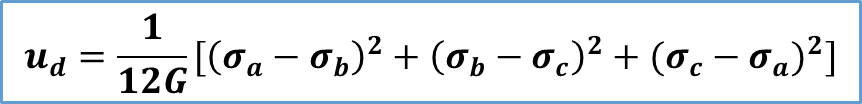

Strain energy density associated with volume change is

Strain energy density associated with distortion (shape change) is

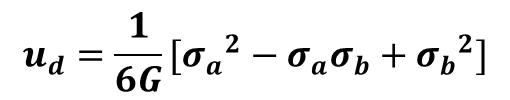

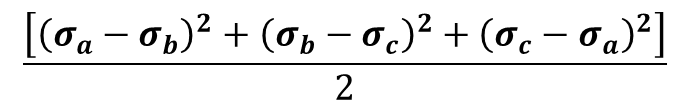

Distortion Energy density is :

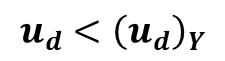

When this distortion energy in an element in a part exceeds the distortion energy density at yield of that same material . That is the point of failure.

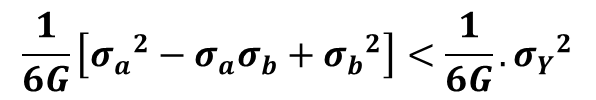

Condition for safe design with unit factor of safety = 1 .

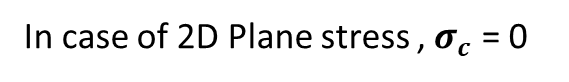

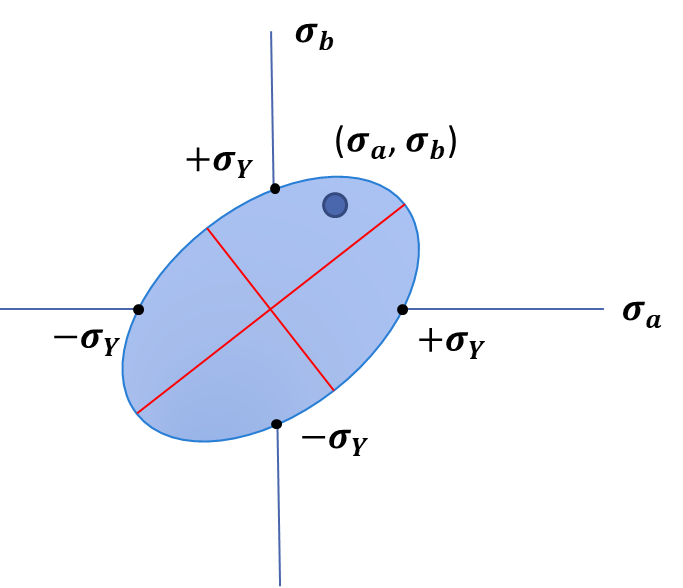

Criteria for Plane stress :

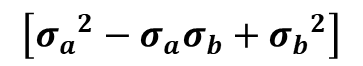

Von Mises Stress definition :

Von Mises stress is a theoretical measure of stress used to predict yielding of ductile materials under complex loading conditions. It combines the different components of stress (normal and shear) into a single equivalent stress value that can be compared with the material's yield strength.

Von Mises Stress for 2D:

Graphical Representation :

Categories: : Mechanism and Machine design

Mufaddal Rasheed

Mufaddal Rasheed