Sheet metal design guidelines

Explore the various design guidelines to be followed for effective sheet metal design in product design

Essential principles that ensure the creation of functional, manufacturable, and cost-effective sheet metal parts. These guidelines encompass various aspects of design, including material selection, bend radii, hole spacing, and tolerances, to optimize the fabrication process.

Holes which can be punched in sheet metal have to be larger than the thickness of the sheet metal.

Spacing between holes should be more than 2 x thickness

Relief for a Bend should be at least 2T in width and Bend radius + T for Length

Bends with corners :

This type of design generally results in thinning at the ball radius corner

Better is to provide relief.

Use flanges and dimples or beads to stiffen Bent parts.

Avoid designs with very deep draws

Flange height should be minimum 3 .5 T

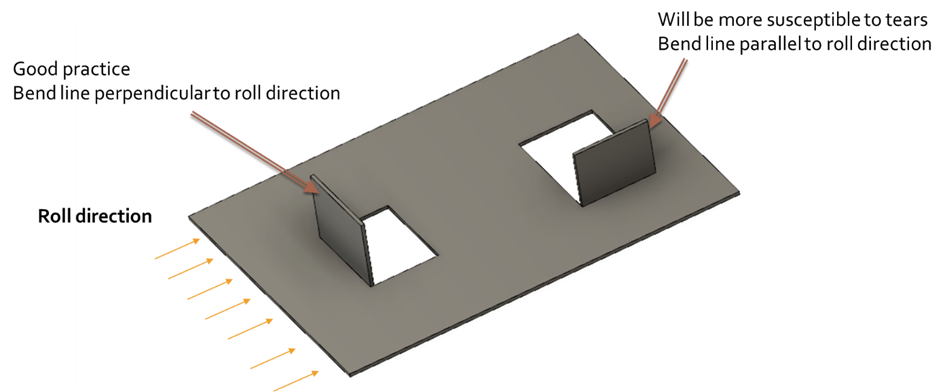

Bending of sheet metal with respect to roll direction directly affects the quality of the Bend

For more content on sheet metal design have a look at the list of articles here :

How to Stiffen Sheet metal design

Categories: : Sheet metal

Mufaddal Rasheed

Mufaddal Rasheed