What is Bend allowance in sheet metal?

How to calculate bend allowance in sheet metal design and why is it important.

What is Bend allowance in sheet metal?

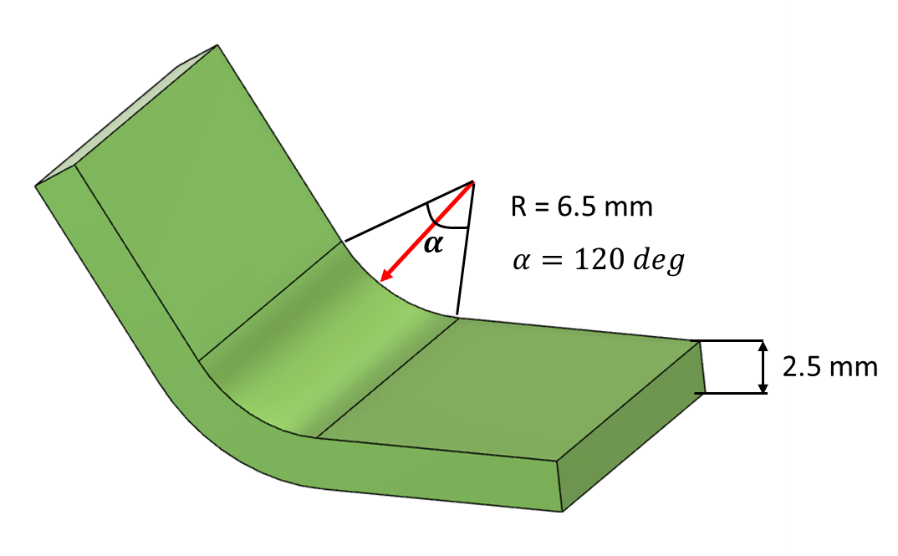

Let us consider a sheet metal bend with the following parameters

Bend allowance is the distance on the flat sheet before bending which will take up the radius after bend.

Bend allowance is nothing but the Arc length of bend at the neutral axis of bend.

What is the K factor?

K factor values are available for standard material grades and gauge thickness with manufacturers. Using which the bend allowance can be calculated.

Example calculation :

Considering a 2.5 mm thick sheet which is bent to a inner Radius of 6.5 mm and bend angle is 120 degrees. What is Bend allowance which has to be considered on flat sheet?

Calculation :

K factor = 0.5

Angle in radians = 120 * 3.1416/180 = 2.0944 Radians

So, Bend allowance = 2.0944(6.5+(0.5*2.5)) =16.232 mm

16.23 mm of length has to be considered in blank of sheet before bending.

To learn about Sheet metal design in deep here is a course which can help :

Basics of Sheet metal design for Mechanical design engineers

For more content on sheet metal design have a look at the list of articles here :

How to Stiffen Sheet metal design

Categories: : Sheet metal

Mufaddal Rasheed

Mufaddal Rasheed